How we do

Our Design Process

At VectorMech Innovations, our process blends creativity with precision engineering — from concept to commissioning. Every project is handled with a proven framework designed to optimize efficiency, minimize risk, and ensure lasting performance in factory and mechanical systems.

Process

Our Process Brings the pulse of your idea

From your initial vision to a fully functioning system, our process is built to support innovation at every stage. We begin by understanding your unique industrial challenges, followed by in-depth design, simulation, and testing. With agile project execution and quality-driven implementation, we ensure that each solution we deliver is tailored, scalable, and built for the future of your industry.

01

Background Research

Every successful project begins with deep research. We analyze your idea, target users, functional requirements, and existing solutions to ensure we’re designing something truly valuable.

Technical and market research

Benchmarking existing products

Understanding user needs and constraints

Material, process, and cost feasibility studies

02

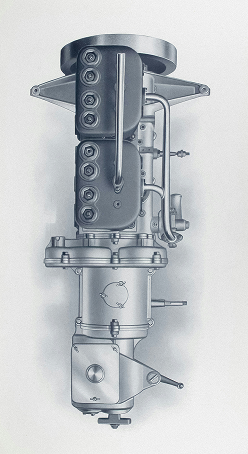

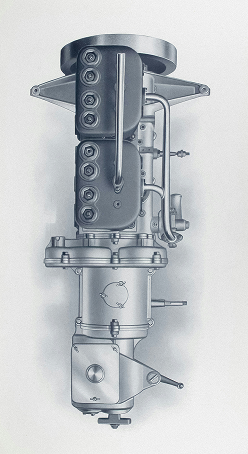

Concepts Development

Exploring Possibilities and Ideating Solutions

We develop multiple design concepts through sketches and rough 3D blocks, testing different approaches for form, function, and efficiency. This is where creativity meets engineering logic.

We develop multiple design concepts through sketches and rough 3D blocks, testing different approaches for form, function, and efficiency. This is where creativity meets engineering logic.

Concept sketching and brainstorming

Functional layout planning

Design iterations and feedback loops

Client input and selection of preferred concept

03

3D Model Designing

Engineering the Details

Once a concept is selected, we move to detailed 3D CAD modeling using industry-standard tools. This step transforms ideas into fully defined components and assemblies.

Once a concept is selected, we move to detailed 3D CAD modeling using industry-standard tools. This step transforms ideas into fully defined components and assemblies.

Solid and surface modeling

Mechanical design of components and mechanisms

Assembly modeling with motion constraints

DFM (Design for Manufacturing) integration

04

Simulation & Verification

Testing Before Building

Before production, we run simulations to validate the design under real-world conditions. This helps reduce cost, material waste, and failure risk.

Before production, we run simulations to validate the design under real-world conditions. This helps reduce cost, material waste, and failure risk.

Structural FEA simulations

Load and stress testing

Material behavior evaluation

05

Production-Ready Design

Ready for Manufacturing

Once the design is finalized and verified, we prepare complete documentation and files for production, ensuring a seamless handoff to manufacturers or prototyping services.

Once the design is finalized and verified, we prepare complete documentation and files for production, ensuring a seamless handoff to manufacturers or prototyping services.

2D technical drawings with tolerances

Assembly instructions and BOM

Exported files for CNC, 3D printing, or mold making

Vendor/manufacturer suggestion (optional)